FAQs

You asked…and we answered!

We’ve compiled these frequently asked questions over the years, and our experts in the engineering, software and service teams have supplied all the answers.

We hope these help – if you need further advice we recommend you search our blog or raise a support ticket.

Automeg FAQs

With high voltage testing (Insulation resistance and HiPot / dielectric testing), it is rarely the test system that defines the testing time. OEMs and specific industries tend to have their own test requirement specification that define:

- Ramp up time (time to charge the wire/harness/net from 0V to test voltage)

- Measurement Dwell (the time during which the high voltage is maintained and the system measures leakage current or insulation resistance)

Here’s an example – a harness with 10 nets needs testing at 1000Vdc. The test specification defines the ramp time as 0.5s (so 1s to ramp to 1000V), and the measurement dwell at 1s. The test time will therefore be at least 100(nets) x [1s (Ramp) + 1s (Measurement)] = 200 seconds. That time is defined purely by the test specification, not the test system.

When you require low voltage testing as well as HV, the low voltage test is nearly negligible compared to the high voltage segment. So, when planning for test time on a harness, the test specification for high voltage test should be your reference document.

If you would like further assistance in calculating accurate test timings, please get in touch. Just send us your test specification and harness/product details, and an application specialist can help.

- Prepare the logo. The logo image needs to be scaled to a suitable size – we recommend 180px wide by 110px high.

- Save the logo in jpeg image format; it must be named CustomerLogo.jpg

- Copy the logo to the following location on the PC hosting MKAT Runner: C:ProgramDataMK Test Systems LimitedReportsLogos. Note: You’ll need to replace the existing file of the same name in this folder.

- That’s it! From now on, all default reports will display your company logo in the top right position as shown below.

Yes, Automeg does have a simple self-test routine. We recommend performing system self-tests at regular intervals to ensure optimal performance of all critical components like switching relays, power supplies, measurement and stimulus circuits, etc.

The frequency of performing self-test depends on several factors such as how often the system is used and how many test points are in your system, among others. It is very common for users to perform self-test at regular intervals such as when the system is turned-on, at the beginning of each shift or prior to executing every job.

You can also set Automeg to run self-test automatically every time the system is switched on.

We have a full blog article answering this question here.

We have a full blog article answering this question here.

Sit tristique montes adipiscing ipsum sociosqu inceptos fusce tempus. Cubilia consectetuer tortor quam dictum integer arcu lectus feugiat sagittis. Litora id enim habitant aptent molestie erat.

BLRT and BLTU FAQs

Once the system is powered on, click the MK software logo to get started.

The login screen will then be displayed – enter the following login details:

- User: operator

- Password: Mktest21013

We recommend that a backup is done first using “MKAT Data Tools”:

- Exit the software

- Run MKAT Data Tools

- Back up all data / config

- Uninstall the software

- Install the new version

Identifying the right tool for aircraft OEM (Original Equipment Manufacturer) bond and loop testing requirements can be complex.

As an MRO, your first point of call should be the AMM (maintenance manual). However, some OEMs are more prescriptive than others. And with a broad range of similar tools available on the marketing all claiming to comply with OEM requirements, how do you know for sure which tool is right?

MK’s range of bond testing tools are the BLTU4, BLRT and ExLRT. These are often mentioned alongside the legacy industry tool, the LRT. To help differentiate between all the tools, we’ve explained which one is recommended for each original equipment manufacturer:

Airbus

All loop resistance testing on Airbus aircraft must be carried out at 1KHz, so the BLTU4 is the right tool. Airbus do not require joint testing, only loop and bond. We can support with proving equivalency to Airbus for using the BLTU4 within your operation – get in touch with us for details.

Boeing

All loop resistance testing on Boeing aircraft must be carried out using 200Hz. In addition to loop resistance testing, Boeing also demand specific joint tests, variance tests and stray current tests – the BLRT is the recommended tool for this.

Both the BLRT and ExLRT are approved for use by Boeing. What’s the difference between the two? The ExLRT is certified as Intrinsically Safe and is therefore the best tool for MROs working on fueled aircraft. However, the BLRT is the tool which has full bond, loop and joint capabilities.

Depending on your requirements and working environment, either of these tools may be suitable for you. They’re both lighter and smaller than the legacy LRT, and can be operated by a single person.

To learn more about the differences between BLRT and the ExLRT, read this article.

Bombardier

Bombardier are aligned with the Airbus specification of 1000Hz, so we therefore recommend the BLTU4.

COMAC

COMAC have specified the use of the BLTU4 tool in the AMM for ARJ21 aircraft models.

Embraer

Embraer follow Boeing in terms of frequency and types of test required, so the BLRT or ExLRT would be the most suitable tools.

Summary

Visit the dedicated product pages for BLRT, BLTU4 and ExLRT to learn more about each of our bond and loop testing tools. To learn more about the differences between our tools and the legacy Boeing-approved LRT, visit our blog and filter by ExLRT.

We have a detailed blog article answering this question here.

ExLRT FAQs

Although both products use the same MK52 couplers, it is not possible to use a BLRT loop or joint cable on an ExLRT or vice versa. Although the cables look the same, the connectors are different which means they can only be used for the specific product they’re designed for.

Clamps are mechanical items which use a physical pressure to pass electrical signal into the UUT (like two wires soldered together). Clamps are therefore used for DC bond testing – we use 1A, 10A and 150A bond clamps.

Couplers magnetically transfer an electrical AC signal into the UUT. They’re used for AC non-intrusive testing of loops and joints because they can pass the current across air gaps. We use MK52 couplers for these measurements and tests. The commonly used i400 clamps are actually couplers, which is confusing!

Simply put, ExLRT Record Mode means you no longer have to manually enter data into a laptop, PC or paper task card when taking measurements.

Operators can measure, review and save data directly in the tool, then update to a PC. For more information, you can download the guide here or read this blog article.

You can send the cable and couplers back to us for repair. To arrange this, please submit a support ticket on the service page and one of our team will be in touch.

Identifying the right tool for aircraft OEM (Original Equipment Manufacturer) bond and loop testing requirements can be complex.

As an MRO, your first point of call should be the AMM (maintenance manual). However, some OEMs are more prescriptive than others. And with a broad range of similar tools available on the marketing all claiming to comply with OEM requirements, how do you know for sure which tool is right?

MK’s range of bond testing tools are the BLTU4, BLRT and ExLRT. These are often mentioned alongside the legacy industry tool, the LRT. To help differentiate between all the tools, we’ve explained which one is recommended for each original equipment manufacturer:

Airbus

All loop resistance testing on Airbus aircraft must be carried out at 1KHz, so the BLTU4 is the right tool. Airbus do not require joint testing, only loop and bond. We can support with proving equivalency to Airbus for using the BLTU4 within your operation – get in touch with us for details.

Boeing

All loop resistance testing on Boeing aircraft must be carried out using 200Hz. In addition to loop resistance testing, Boeing also demand specific joint tests, variance tests and stray current tests – the BLRT is the recommended tool for this.

Both the BLRT and ExLRT are approved for use by Boeing. What’s the difference between the two? The ExLRT is certified as Intrinsically Safe and is therefore the best tool for MROs working on fueled aircraft. However, the BLRT is the tool which has full bond, loop and joint capabilities.

Depending on your requirements and working environment, either of these tools may be suitable for you. They’re both lighter and smaller than the legacy LRT, and can be operated by a single person.

To learn more about the differences between BLRT and the ExLRT, read this article.

Bombardier

Bombardier are aligned with the Airbus specification of 1000Hz, so we therefore recommend the BLTU4.

COMAC

COMAC have specified the use of the BLTU4 tool in the AMM for ARJ21 aircraft models.

Embraer

Embraer follow Boeing in terms of frequency and types of test required, so the BLRT or ExLRT would be the most suitable tools.

Summary

Visit the dedicated product pages for BLRT, BLTU4 and ExLRT to learn more about each of our bond and loop testing tools. To learn more about the differences between our tools and the legacy Boeing-approved LRT, visit our blog and filter by ExLRT.

We have a detailed blog article answering this question here.

We have a detailed blog article answering this question here.

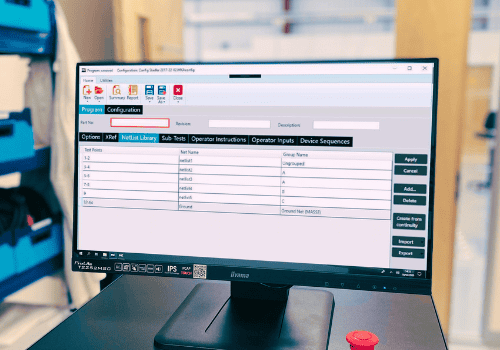

MKAT Software FAQs

MKAT Editor software does not require a login. For the Runner software, systems are set up with 3 default logins. The user names are not case sensitive but the passwords are:

- User name: Administrator. Password: MKtest2016

- User name: Advanced Programmer. Password: MKtest2013

- User name: Operator. Password: Mktest21013

No, MK Test Systems developed MKAT to make testing simpler, automated and to save the user time and money. MKAT is supplied with a user guide.

We also offer monthly training webinars which are free of charge. Details and dates of these are on the training page. If dedicated onsite training is required, just ask your MK Sales Manager or complete an enquiry form on the training page.

We have a full blog article answering this question here.

We no longer support our gen2 software so recommend that all customers upgrade to gen3 MKAT. For more FAQs about this topic, read our dedicated article here.

- Prepare the logo. The logo image will need to be scaled to a suitable size – we recommend 180px wide by 110px high.

- Save the logo in jpeg image format; it must be named CustomerLogo.jpg

- Copy the logo to the following location on the PC hosting MKAT Runner: C:ProgramDataMK Test Systems LimitedReportsLogos. Note: You’ll need to replace the existing file of the same name in this folder.

- That’s it! From now on, all default reports generated by MKAT Runner will display your company logo in the top right position as per the example shown below.

We occasionally have customers contacting us for help when they’re creating an MKAT test program. The conversation is usually along the lines of “I’ve run the APG in the MKAT Editor but it didn’t create a program. Where did I go wrong?”.

This fairly common query can be resolved with just a few changes – we’ve written a dedicated article here.

- In the Runner, go to Configuration and select the Parameters tab

- Select the desired report from the Default Report menu

- Apply the change

From now on, this report will be automatically selected to display the test results.

We have a detailed blog article answering this question here.

For example, with a harness that goes into a junction box and splits off into multiple different looms, can I just map the connections at each end in the netlist and map the test point connections at either end of the harness in the Xref?

The ability to resolve internal connections is only there for the occasions where you have not already mapped the end to end connections. So, if you have an internal component such as a terminal block and you have already worked out the route through the component, then yes you simply enter the extremity From-To details in the netlist and XRef and the system will test from the one extremity to the other.

One tip is to put the terminal block reference (or other component) in the “connection detail” field in the netlist, so when the report shows a failure between the two extremities you will see on the report that the circuit passes through a terminal block and you will know to go look there for the fault.

Driven by our goal of simplifying an automatic test sequence for the end user, the new generation of software keeps your testing process as simple as possible.

Operator instructions and prompts can easily be added to any program, with automatic test reports, export to quality systems without manual intervention and fault diagnosis tools assisting the operator in informing of the nature of the fault and what to do next. This leads to easier, time saving and traceable test programs. More details can be found on the MKAT page.

MK Test Systems stopped supporting Gen2 after 31 Dec 2020. This included updates, amendments revisions or improvements for Gen2 software.

A lot of features have been included in MKAT, and more are on the roadmap to be added in future versions. Details of upcoming new features are on the MKAT page and also on our Tech::Lab page, which is dedicated to sharing our NPD news.

A very few limited number of features will not be in MKAT Gen3. To check if a feature you use is included, please ask your MK Test Systems Sales Manager, or email sales@mktest.com.

MKAT includes a Gen2 to Gen3 translator and generally, Gen2 test programs will translate in less than a minute. Get in touch with details of your current Gen2 release revision and we will advise if there are likely to be any issues.

MKAT also includes a powerful APG (Automatic Program Generation) toolset that allows you to create programs from imported source net/circuit data in seconds. More complex programs may need some manual re-configuration to enable you to take full advantage of MKAT.

The Program Version displays on our standard reports by design, so it can’t be removed directly. However, there are two options for achieving a more customised look:

- Custom report option: For customers who need full control over what appears on their reports, we offer custom report setups. With a custom report, you can specify exactly what you want displayed. While this option does involve additional time and costs, it’s suitable for customers who need a tailored reporting solution. Just keep in mind that because custom reports require specific updates whenever we release new software, future updates may need a bit of extra planning.

- Request a software change: An alternative is to request a software change that would allow the program version to be hidden across all standard reports. This route benefits everyone, as it makes the option available to all customers with minimal maintenance during software updates.

Both options provide flexibility, and we’re here to help make sure your reporting needs are met. For either option, please raise a support ticket to get started.

Portable Automeg FAQs

Portable Automeg is about the size of a small suitcase. The system is housed in a protective Peli case which has an extended handle and wheels and an IP66 rating.

External dimensions are around 600 x 400 x 260mm, depending on the final system specification.

The Peli case is ruggedised, with anti-vibration mounts fitted.

Yes it can.

The Portable Automeg was originally designed for - and continues to be used in - submarines, where space is at an absolute premium. A removable lid is optional but vital in certain applications.

Yes! We've designed the Portable to as closely replicate the capability of the standard Automeg systems, and this includes the software and therefore creation and running of test programs.

Go to the MKAT software page to learn more.

Typically yes, but we can also offer a battery version.

Yes. A ticket printer option is available.

The Portable Automeg can have up to 512 test points (256 test points maximum for 4 wire measurements).

Yes. We offer the Portable Automeg as an 'E' model which is capable of performing excitation measurements. There is an option to include a fixed internal power supply to enable functional testing on the unit under test (UUT).

RTS FAQs

Yes, the RTS system is scalable and will automatically detect new nSat and uSat devices when added. This means that the system can be expanded at a later date by adding more MAG connectors and umbilical sections to accommodate more nSat or uSat devices.

At this time, Umbilical sections are available in lengths of 0.5m, 1m, 3m, 5m, 10m, 15m, 20m, 30m & 50m. The total length of a single umbilical must not exceed 100m.

The total number of nSat or uSat devices on one umbilical must not exceed 48.

The Umbilical Connection Module (UCM) allows up to 4 umbilicals connected at each time.

The uSat has a higher number of test points available than the nSat and can be easily thought of as 2, 4 or 6 nSats in one box!

If you have a high density of connectors and test points in one location a uSat can be used giving you up to 360 test points to connect everything up at once and only one Umbilical connection (MAG connector) required.

Speak to us about custom formats using the uSat hardware with even higher test point densities such as ARINC 404/600 housings for aerospace applications.

Nano Satellite (nSat)

Micro Satellite (uSat)

Absolutely! All MK Test System products use the MKAT Gen3 Software suite and this includes the RTS system. This means that you will already be familiar with all the common functions. Importing and running test programs, viewing results and using advanced features such as Manual Mode and Probe Mode within the MKAT Runner application are all the same as MKAT for Automeg. Creation of test programs and management of the system is also still done using the MKAT Editor and you can even use the powerful functions of the Automatic Program Generator (APG) tool to generate RTS programs.

To make the most of the advanced features of RTS, a new RTS sub-test is available. This is a new display screen allowing the user to view and sort results in real time whilst the scanning is in progress.

Along with this, some new features for interface harness management and hardware configuration have been introduced to the MKAT Runner to make the operator’s life easier.