MK Test Systems has been designing automatic test equipment for the world's most demanding industries since 1992.

MK Test have evolved into a global business dedicated to utilising the latest technology to help our customers improve their testing. To find out how we can help you test your best, get in touch with us today.

Do you need a wire harness test system, a bond or loop resistance tester, something that can handle it all, or have a new testing challenge?

If you know what you need, click here to see our products.

Whether it's planes, trains or automobiles, we supply test systems for vehicles as well as for equipment in emerging markets such as hybrid fibre-copper cables and green energy.

Click to see what solutions we can offer your industry.

Our customers' most common applications are listed here, with example use cases and recommended products.

Start here if you know what you need to test but aren't sure which MK product you'll need to do it.

The increasing use of hybrid cables and connectors combining copper and fibre is driving demand for an automatic test system with both capabilities.

Our new compact COTS test system integrates these functions into a single test system. Find out more information, including our progress towards an industrialised solution.

Our complete Test System Solution is designed for MRO teams – whether you're working on aircraft engines, LRUs, or APUs.

This is a complete package configured for your specific requirements; comprising the Automeg test system, interface cable set, and pre-written test program.

In May, we delivered a tech talk on fault analysis at the 2025 EWPTE show in Milwaukee.

Today’s test systems are often underused, being used only to confirm a pass/fail. Get practical advice on how to generate, store, and analyse data to improve efficiency, reliability, and future readiness.

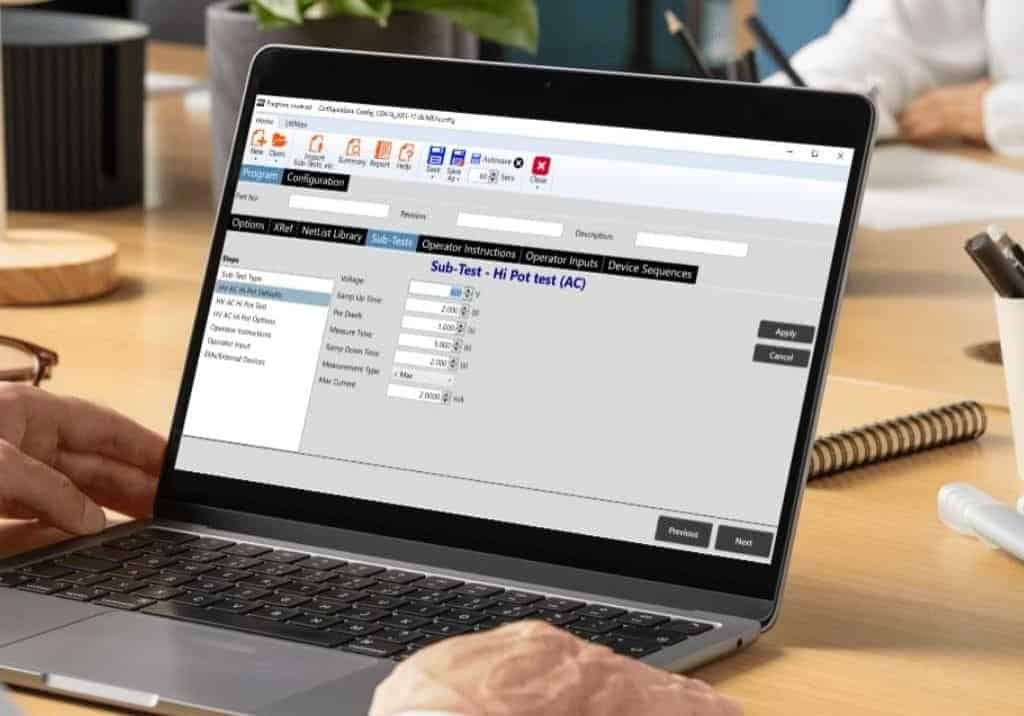

The latest version of MKAT - our test management software - was released in October 2025.

Get more info on the new features in - and request access to - the latest version by clicking on the button below.

You can also sign up for a mailing list for automatic notifications via this link.

We understand your market

With decades of experience in our main industries across our sales and engineering teams, you won’t have to spend time explaining your requirements, we’ll just ‘get it’.

We get measurable results

Our test systems consistently deliver measurable ROI, faster test times, better efficiencies, and reduced operational costs for our customers.

We have a global reach

With team members and trusted specialist reps and distributors spanning EMEA, the Americas, and Asia, we offer local support backed by a global business.

We have a proven track record

We’ve designed, built and supplied over 3000 test systems to 38 countries. Our products are approved by several global OEMs in aerospace and rail.

During my meetings with MK Test, there was a clear advanced technical competency on the systems and flexibility to accommodate the customer as much as possible."

Test and measurement expertise, for all industries.

Our team of application experts have designed test systems for dozens of industries over MK’s 30+ year history.

We can advise on the best solution for your sector and specific application.