Regular preventative maintenance for electrical test systems is essential to maintaining accuracy, reliability and uptime. Whether you’re using MK Test Systems equipment in production, MRO or quality-assurance environments, a consistent maintenance routine helps to reduce downtime, preserve test accuracy and extend system life. From Automeg automatic wiring testers to RTS real-time scanning systems and bond-testing instruments such as the ExLRT, BLRT and BLTU4C, each product category benefits from proactive care.

Why Preventative Maintenance Matters

When it comes to electrical testing, reliability is everything. Regular preventative maintenance is one of the best ways to ensure your systems continue to deliver accurate, repeatable results day after day.

Preventative maintenance is recognised globally as an essential practice for maintaining reliability and safety across industries. For a useful overview, the ANSI overview of preventive maintenance standards provides a useful summary of the key frameworks and requirements that guide these best practices.

Our systems are built for demanding environments – from aircraft production lines to maintenance hangars – and designed to run reliably for many years. But as with any high-performance equipment, proactive maintenance makes a real difference.

Preventative maintenance helps to:

-

- Reduce unexpected downtime by identifying issues early.

-

- Preserve measurement accuracy by ensuring calibration and verification routines are followed.

-

- Extend equipment lifespan by keeping mechanical, electrical and software components in good order.

-

- Support compliance with customer, regulatory and quality-standards requirements.

In the aviation sector, preventative maintenance is a regulated and well-defined activity. The FAA Advisory Circular on Preventive Maintenance (AC 43-12A) outlines approved methods and practices that highlight the importance of planned maintenance for safety and reliability.

Below, we’ve outlined system-specific guidance to help you get the best long-term performance from your MK Test Systems equipment.

Automeg systems

Our Automeg automatic cable & wire harness testing systems are designed for continuity resistance measurements, short-circuit checks and high-voltage insulation testing (DC up to 8000 Vdc in some formats), with optional modules for HiPot AC, capacitance measurements, and functional testing.

Recommended preventative maintenance includes:

-

- Relay and switching module inspection. Ensure switching cards are functioning correctly and not showing wear or drift.

-

- Calibration verification. Check continuity, resistance, insulation and HiPot modules are within tolerances.

-

- Connector and interface inspection. Clean contacts, verify no bent pins, check harness stability.

-

- Software updates. Ensure your MKAT software is up to date, to support new test formats and maintain compatibility.

-

- Environmental checks. Verify enclosures, cooling fans and ventilation are free of dust, debris and obstruction.

Suggested interval: Every 6–12 months depending on usage intensity, environment and number of test cycles.

RTS systems

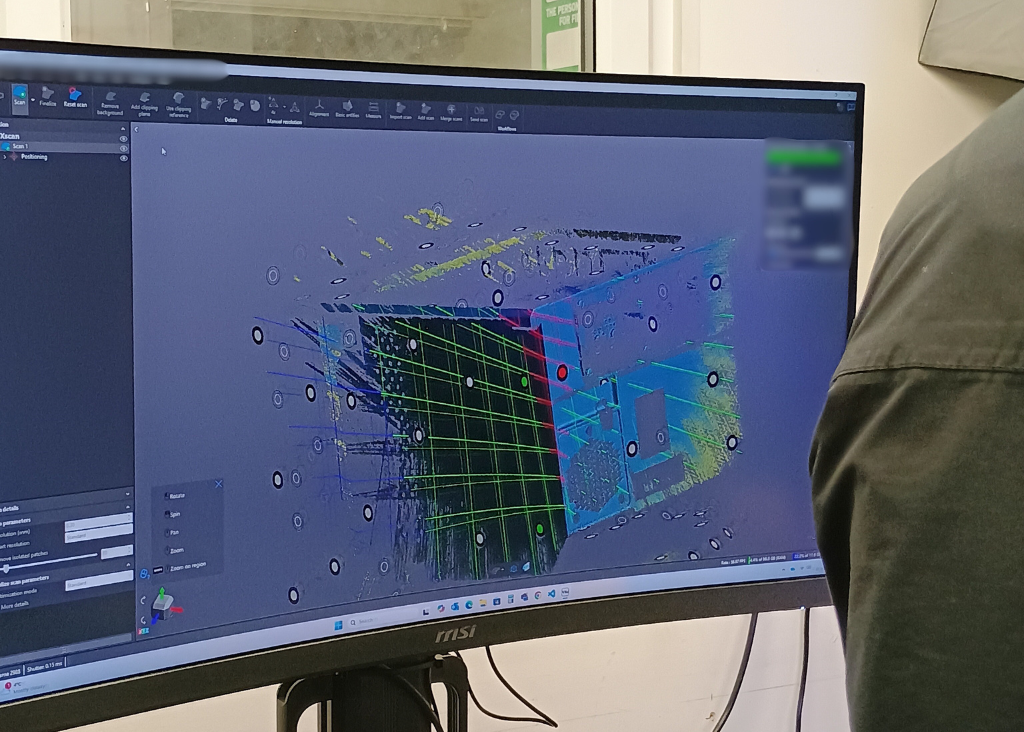

Our RTS (Real Time Scanning) uses miniaturised, modular switching directly at the Unit Under Test (UUT) to enable near-instantaneous measurement, with very short interface cables (reducing traditional cabling by up to 90%).

Designed for high-pin-count assemblies, in-build-harness hookup and other demanding applications, RTS offers real-time diagnostics and rapid deployment.

Key areas for preventative maintenance:

-

- Satellite modules, umbilicals and MAG connectors. Check mechanical connection health, cable integrity and connector pins.

-

- Calibration checks. Although RTS uses low-voltage scanning, ensure continuity/short/connection status measurements remain accurate.

-

- Software diagnostics. Review MKAT reports, verify all measurement channels are functioning and reporting correctly.

-

- Visual inspection. Confirm system modules are free from damage, cooling is adequate, and any indicators (LEDs) are working.

-

- Firmware & driver updates. To maintain compatibility with interface harnesses, PC OS and test program files.

Suggested interval: Given the critical nature and often mobile/field-use of RTS systems, an annual check is appropriate, with interim visual or functional checks quarterly.

Bond Test Systems (ExLRT, BLRT & BLTU4C)

Bond testing equipment (such as the ExLRT, BLRT and BLTU4C) is used to verify structural or electrical integrity of bonds, loops and joints – especially in aerospace, defence and high-reliability applications.

Preventative maintenance for bond testers should include:

-

- Lead and probe inspection. Check for wear, contamination or damage to leads, fixtures and probes.

-

- Calibration and verification. Confirm test currents, measurement accuracy and proper operation of measurement circuits.

-

- Battery/power supply checks (for portable units). Replace aging batteries and verify power integrity.

-

- Visual inspection and cleaning. Keep connectors, enclosures, displays and user interface in good condition.

-

- Software updates and data-management checks. Ensure test results are logged correctly and device firmware is current.

Suggested interval: Annual calibration plus a detailed check; field or mobile use systems may benefit from mid-year inspection.

How We Can Help

We offer a comprehensive range of service options including calibration, system health checks, on-site service and training. Our dedicated team of service engineers can help you develop a preventative maintenance schedule that aligns with your usage patterns, environment and operational demands.

To discuss your maintenance requirements or book a system review, contact our team by completing a support ticket.