Wire harnesses are the unsung heroes of modern electrical systems, connecting critical components and enabling seamless energy and signal transfer. However, their reliability is paramount, especially in industries like aerospace, automotive, and renewable energy, where failures can have catastrophic consequences. Automation is revolutionising how wire harnesses are designed, assembled, and tested, ensuring unmatched reliability and performance.

Why Wire Harness Reliability is Critical

Wire harnesses are essential in complex electrical systems, serving as the backbone for connectivity. Their reliability is critical for:

- Safety: Faulty connections can lead to electrical fires, equipment malfunctions, or accidents.

- Performance: A reliable harness ensures optimal functionality and prevents system downtime.

- Longevity: Quality harnesses withstand wear and environmental stress, reducing the need for replacements.

Industries such as aerospace and automotive depend on wire harnesses to power systems, control signals, and ensure fail-safe operation.

Common Challenges in Ensuring Wire Harness Reliability

- Human Error: Manual assembly or testing can lead to inconsistencies and errors.

- Environmental Stress: Exposure to heat, vibration, and moisture can degrade harness performance over time.

- Complexity: Modern systems require wire harnesses with intricate designs, increasing the likelihood of issues.

- Inspection Bottlenecks: Traditional testing methods often fail to detect subtle defects or wear.

The Role of Automation in Enhancing Wire Harness Reliability

Automation addresses these challenges by introducing precision, consistency, and efficiency into the production and testing of wire harnesses. Here’s how:

-

Accurate Assembly

Automated systems ensure that each wire, connector, and terminal is precisely aligned and secured, reducing assembly defects.

-

Thorough Testing

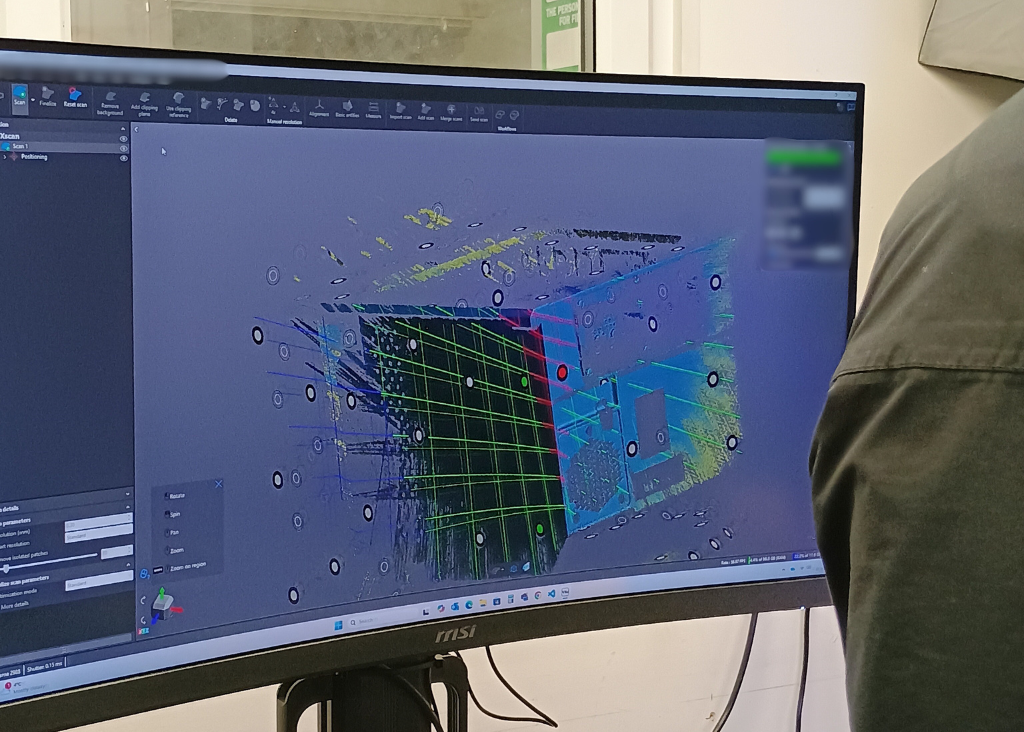

Advanced systems, like those provided by MK Test, verify the integrity of connections, insulation, and continuity in real-time. This prevents latent issues that may arise in the field.

-

Environmental Simulation

Automation enables harness testing under simulated real-world conditions, such as high temperatures, vibrations, and humidity, ensuring durability in extreme environments.

-

Scalability

Automated processes can handle large-scale harness production without compromising quality, meeting the demands of industries like automotive and aerospace.

-

Data-Driven Insights

Integrated systems provide detailed reports and analytics, enabling continuous improvement in harness design and production.

MK Test’s Advanced Solutions for Wire Harness Reliability

MK Test’s automated solutions are designed to revolutionise how wire harnesses are tested and maintained. Our systems are trusted by global leaders in aerospace, automotive, and energy for their unparalleled precision and efficiency.

Key Benefits of MK Test Systems

- Comprehensive Testing: Detects even the smallest defects in continuity, resistance, and insulation.

- Customised Solutions: Tailored to meet the unique needs of each industry and application.

- Real-Time Reporting: Provides actionable insights to optimise production and maintenance.

- Global Support: Backed by a dedicated team ensuring smooth implementation and operation.

As industries demand increasingly complex and reliable electrical systems, automation is transforming how harnesses are produced and tested. By enhancing precision, scalability, and efficiency, automation ensures harnesses meet the highest standards of reliability and performance. MK Test’s advanced solutions are at the forefront of this transformation, providing industries with the tools needed to optimise their operations and minimise risks.

Looking to enhance the reliability of your wire harnesses? MK Test’s automated solutions offer the precision and efficiency your business needs. Contact us today to learn more:

Visit: MK Test Products

Call: +44 (0)1823 661100

Email: sales@mktest.com

FAQs

Q1: How does automation improve wire harness reliability?

A1: Automation eliminates human errors, ensures consistent assembly and testing, and allows for thorough environmental simulations, improving durability and performance.

Q2: What industries benefit the most from reliable wire harnesses?

A2: Aerospace, automotive, defence, and renewable energy industries rely heavily on reliable harnesses for safety and operational efficiency.

Q3: Can MK Test’s solutions adapt to custom wire harness designs?

A3: Yes, MK Test systems are highly adaptable and can be customised to test harnesses of varying complexities and designs.