Testing electrical circuits is a critical part of ensuring system reliability, performance, and safety. Whether in industrial automation, aerospace, or renewable energy, precise and efficient testing guarantees that systems operate as intended, preventing costly failures. Without proper testing, undetected faults can lead to malfunctions, downtime, or even catastrophic failures. Advances in automated testing technology now allow for greater accuracy, efficiency, and compliance with industry regulations.

In this blog, we’ll explore key considerations, methods, and how MK Test’s automated testing systems can revolutionise the way you test, reducing errors, improving consistency, and enhancing overall operational efficiency.

Why Testing Electrical Circuits is Essential

Electrical circuits are the backbone of modern technology. Whether in aircraft, power grids, or industrial machinery, ensuring these circuits function correctly is paramount. Testing these circuits ensures:

- Safety: Faults in circuits can lead to overheating, electrical fires, or system failures.

- Compliance: Many industries require testing to meet strict standards, such as ISO 9001 or BS 7671 in the UK.

- Reliability: Regular testing identifies potential issues before they escalate, ensuring optimal system performance.

- Cost Savings: Detecting and resolving faults early prevents expensive repairs and minimises downtime.

By incorporating automated solutions, businesses can achieve higher levels of compliance, operational reliability, and safety, reducing the risk of system failures.

Methods for Testing Electrical Circuits

Various methods are used to evaluate circuit performance and safety. The most common include:

- Continuity Testing

Ensures a complete path for current in the circuit. A continuity test detects breaks or poor connections that can disrupt operations. - Insulation Resistance Testing

Evaluates the condition of insulation to prevent leaks or electrical hazards. This is vital in high-voltage systems to maintain safety and longevity. - Voltage Testing

Confirms proper voltage levels within circuits, avoiding overloading and potential damage to components. This ensures devices receive the correct power supply. - Earth Loop Impedance Testing

Ensures effective earthing in systems, reducing risks of electrical shock or fire in fault conditions. Proper earthing is essential for safety and compliance. - High-Potential (Hi-Pot) Testing

Subjects circuits to higher-than-normal voltages to verify insulation integrity and detect weak points that could cause failures under real-world conditions.

The Challenges of Manual Circuit Testing

Manual testing has been the traditional approach for verifying circuit integrity, but it comes with limitations:

- Inconsistent Results: Variations in results due to human error or lack of standardisation.

- Extended Downtime: Increased time to identify and resolve faults leads to inefficiencies.

- Safety Risks: Higher likelihood of exposing testers to electrical hazards, especially in high-voltage environments.

- Limited Scalability: Manual testing is not practical for large-scale production or complex systems that require rapid testing.

With the growing complexity of electrical systems, industries require a faster, safer, and more reliable testing approach—one that automated systems provide.

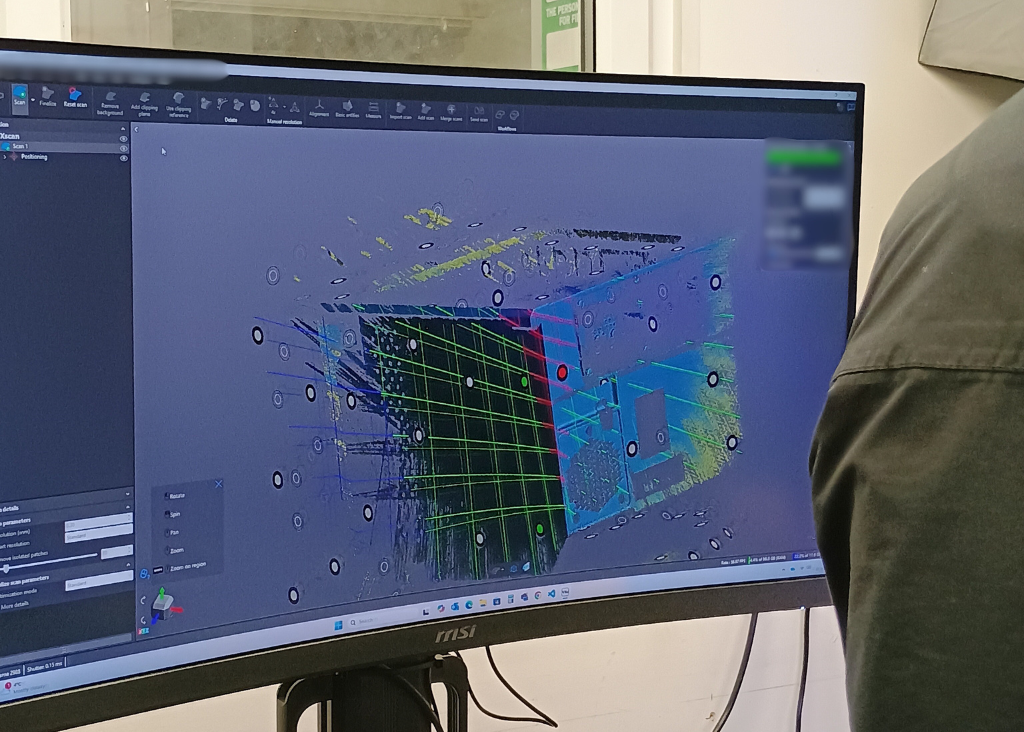

Automating Electrical Circuit Testing with MK Test

MK Test provides cutting-edge automated test systems that transform how you test electrical circuits. With advanced technologies designed for complex systems, our solutions offer:

- Speed and Efficiency: Automating repetitive tests drastically reduces testing time, leading to faster project completion.

- Accuracy: Eliminates human error for precise and reliable results, ensuring compliance with stringent industry standards.

- Safety: Minimises exposure to hazardous conditions with remote-controlled testing, protecting operators.

- Versatility: Adaptable to a wide range of applications, from aerospace and defence to renewable energy and rail.

- Seamless Compliance: Automated reporting ensures accurate documentation for audits and regulatory approvals.

With real-time data collection, predictive maintenance capabilities, and seamless integration with existing workflows, MK Test systems provide a future-proof solution for electrical circuit testing.

Key Features of MK Test Systems

- Customisable Solutions

Tailored to specific industries and applications, including aerospace, rail, and power generation. Our systems adapt to different testing requirements and regulations. - Data Integration

Automated reporting for seamless compliance, analysis, and traceability. Test results can be recorded, stored, and reviewed for quality assurance. - Global Support

With a network of experts, MK Test provides unparalleled customer service, ensuring you get the most from your automated testing system. - Scalability for Future Growth

Our solutions are designed to scale with your business, allowing you to handle increased testing demands without compromising speed or accuracy.

For businesses looking to enhance efficiency, accuracy, and compliance in testing electrical circuits, MK Test’s automated systems are the proven solution.

Get in Touch with MK Test

Ready to upgrade your electrical circuit testing process with automation? Our experts can help you find the perfect solution tailored to your needs.

📞 Call: +44 (0)1823 661100

📧 Email: sales@mktest.com

🔗 Visit: MK Test Products

Let’s revolutionise how you are testing electrical circuits—with precision, reliability, and automation.

Testing Electrical Circuits FAQs

Q1: What industries benefit by automating testing electrical circuits?

A1: Industries such as aerospace, rail, defence, and renewable energy benefit significantly due to the complexity and high standards required for electrical systems.

Q2: How does automating testing electrical circuits improve test consistency?

A2: Automated systems remove human error by using pre-set parameters, ensuring consistent and repeatable results every time.

Q3: Can MK Test systems integrate testing electrical circuits with existing workflows?

A3: Yes, MK Test systems are highly adaptable and can be customised to integrate seamlessly with your current processes.