In an era of rapid technological advancement, the demand for efficient and reliable test equipment has never been higher. Industries across the globe rely on accurate testing to ensure safety, compliance, and optimal performance. As systems grow more complex, the traditional methods of testing are no longer sufficient. Automation and innovation are now redefining the capabilities of modern test equipment.

This blog explores how these advancements are transforming industries, delivering faster, safer, and more accurate testing solutions.

The Challenges of Traditional Equipment

While traditional test equipment has served industries well, it faces limitations that can hinder progress in today’s fast-paced world:

- Time-Consuming Processes: Manual testing often requires significant time, delaying production timelines.

- Human Error: The accuracy of results is susceptible to mistakes, especially in high-pressure environments.

- Limited Scalability: As testing demands increase, traditional systems struggle to keep up with the scale and complexity.

These challenges underscore the need for innovative solutions that can address the growing demands of modern industries.

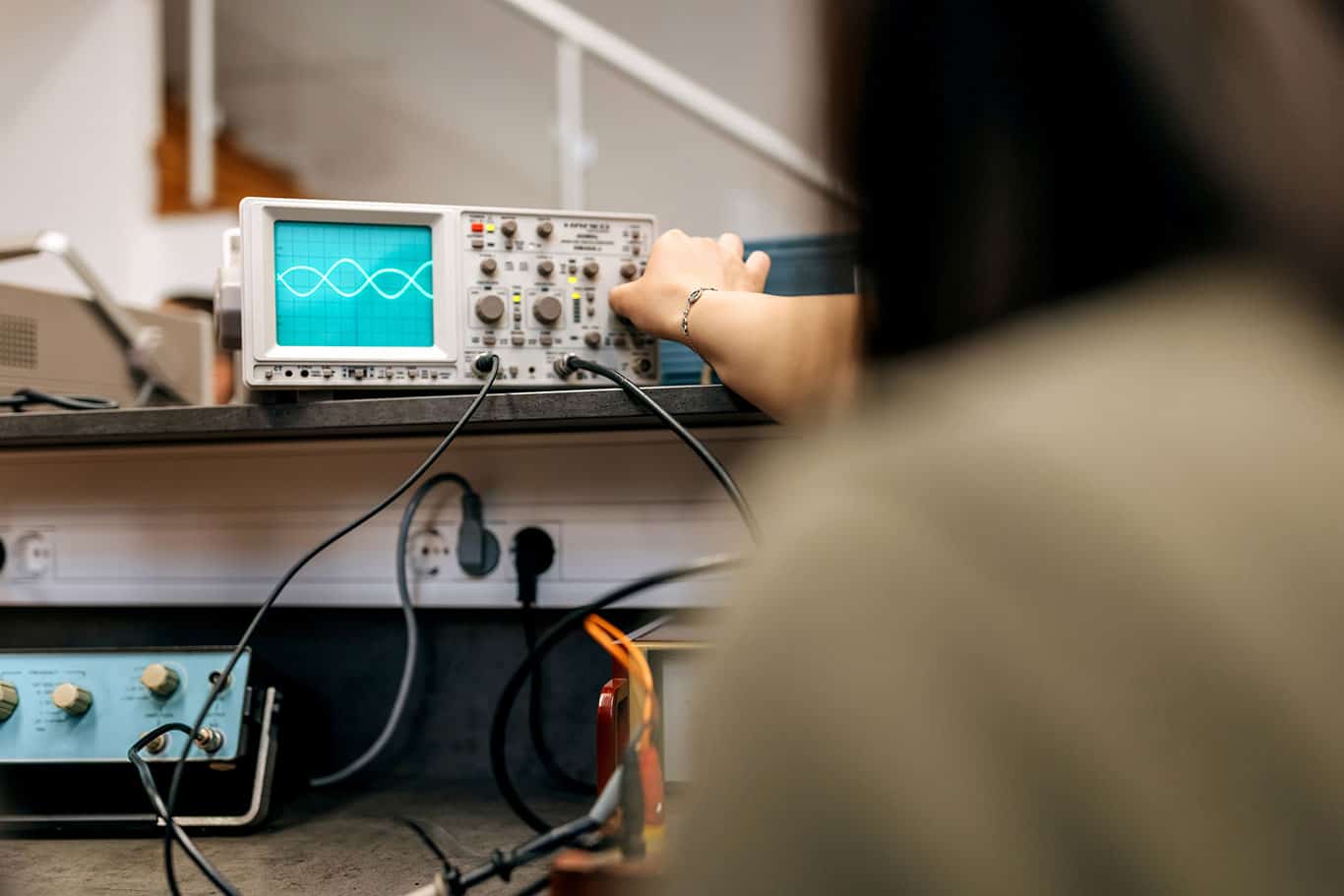

The Role of Automation

Automation is revolutionising test equipment by delivering significant improvements in efficiency, precision, and scalability. Key benefits include:

-

Enhanced Accuracy

Automated systems eliminate human error, ensuring consistent and reliable results every time. Advanced fault detection capabilities identify issues that manual processes might miss.

-

Increased Efficiency

Automation reduces testing time by handling multiple tasks simultaneously, accelerating production cycles without compromising quality.

-

Customisable Testing Protocols

Modern systems allow users to tailor testing procedures to meet specific requirements, ensuring compliance with industry standards.

-

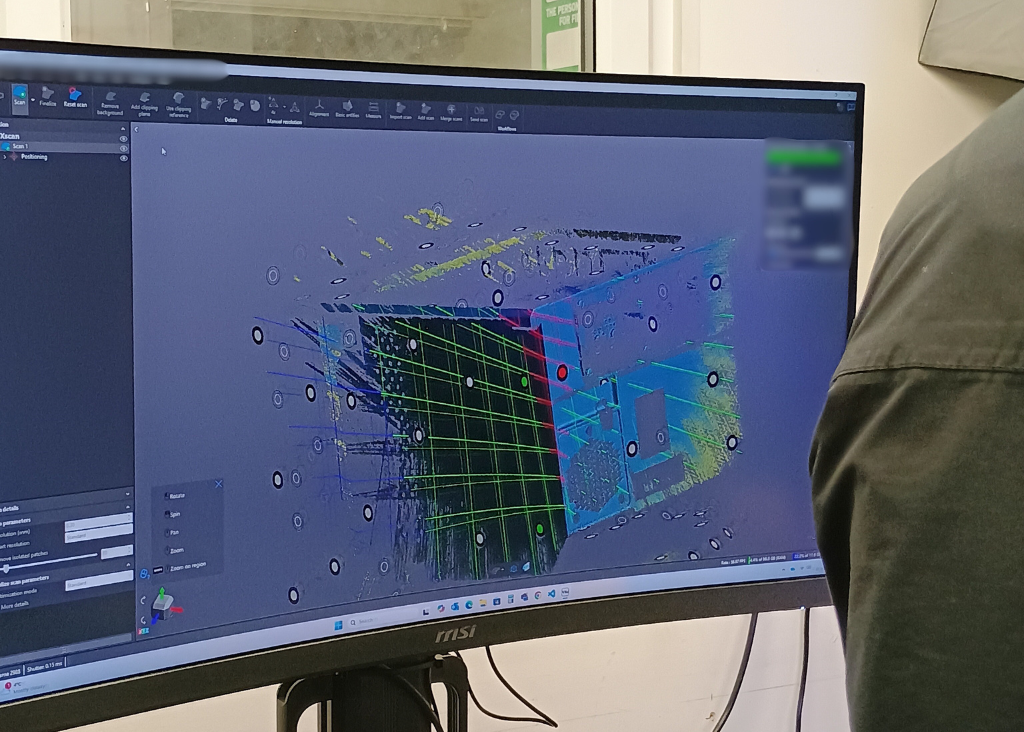

Real-Time Data Analysis

Automated test equipment generates detailed reports and insights in real time, enabling faster decision-making and improved system designs.

-

Scalability

Whether you’re testing small batches or large-scale systems, automated equipment can adapt to the demands of any operation.

Innovative Features Driving Modern Test Equipment

- AI Integration

Artificial intelligence enhances the functionality of test equipment by enabling predictive maintenance, pattern recognition, and self-learning capabilities. - IoT Connectivity

Internet of Things (IoT) integration allows test equipment to communicate with other systems, offering remote monitoring and data centralisation. - Sustainability

Modern test equipment is designed with energy-efficient components and recyclable materials, aligning with global sustainability goals. - Advanced User Interfaces

Touchscreen interfaces and intuitive software make operating test equipment simpler and more user-friendly.

Applications

Automated and innovative test equipment is transforming a wide range of industries:

- Aerospace: Ensures the safety and reliability of mission-critical systems in aircraft.

- Automotive: Validates the performance of wiring harnesses, batteries, and advanced driver-assistance systems (ADAS).

- Energy: Tests renewable energy systems, including wind turbines and solar panels, for efficiency and durability.

- Manufacturing: Streamlines testing for industrial machinery and electronic components.

Learn more about how MK Test’s solutions can address these applications here.

Why Choose MK Test?

At MK Test, we specialise in cutting-edge automated solutions designed to optimise testing processes across industries. Our systems offer:

- Unmatched Precision: Detect the smallest faults with advanced fault detection capabilities.

- Time-Saving Automation: Accelerate testing cycles while maintaining the highest standards.

- Customisation Options: Adapt testing protocols to meet specific needs and regulations.

- Actionable Insights: Benefit from comprehensive reporting and real-time data analysis.

Explore our full range of products and how they can revolutionise your operations by visiting our product page.

The Future of Test Equipment is Here

The integration of automation and innovation in test equipment is transforming the way industries ensure safety, reliability, and efficiency. As technology continues to evolve, businesses must embrace these advancements to stay competitive and meet the demands of modern systems.

If you’re ready to revolutionise your testing processes, contact MK Test today at +44 (0)1823 661100 or email us at sales@mktest.com.

FAQs

Q1: How does automation improve the reliability of test equipment?

A1: Automation eliminates human error, provides consistent testing procedures, and delivers accurate results for reliable system verification.

Q2: Can automated test equipment handle high-volume operations?

A2: Yes, automated systems are designed to scale seamlessly, making them ideal for high-volume production environments.

Q3: Is modern test equipment eco-friendly?

A3: Many advanced systems are designed with energy-efficient components and recyclable materials to support sustainability initiatives.