Understanding Insulation Resistance Test Voltage

Insulation resistance testing is a critical process used to verify the integrity of electrical insulation. The insulation resistance test voltage refers to the specific voltage applied during these tests, ensuring that electrical systems can operate safely without leakage currents or breakdowns.

Selecting the correct test voltage is essential—applying a voltage that is too low may fail to detect insulation weaknesses, while an excessively high voltage could damage insulation. Engineers and technicians must follow industry standards to determine the appropriate voltage for each system.

This blog explains how insulation resistance test voltage is selected, why it matters, and how automation can improve accuracy and efficiency.

How Insulation Resistance Test Voltage Is Determined

The voltage used in insulation resistance testing is based on the operating voltage of the equipment and the testing standards applicable to the industry. The general guidelines for insulation resistance test voltage are:

- Low-Voltage Systems (Up to 1 kV): Test voltage of 500V to 1,000V

- Medium-Voltage Systems (1 kV to 33 kV): Test voltage of 2,500V to 5,000V

- High-Voltage Systems (Above 33 kV): Test voltage of 10,000V or higher

Manufacturers and regulatory bodies, such as the IEC (International Electrotechnical Commission) and IEEE (Institute of Electrical and Electronics Engineers), provide guidelines for selecting the correct test voltage to ensure accurate and safe testing.

Why Test Voltage Matters

- Ensures Reliable Fault Detection

Applying the right insulation resistance test voltage helps identify insulation weaknesses, degradation, or contamination that could lead to electrical failures. - Prevents Overstressing Insulation

Using an excessively high voltage can degrade insulation over time, leading to premature failure. Proper voltage selection ensures the test is effective but non-destructive. - Maintains Compliance with Industry Standards

Electrical safety regulations define acceptable test voltages for different equipment types. Adhering to these standards ensures regulatory compliance and operational safety.

Industry Applications for Insulation Resistance Testing

Aerospace & Defence

Aircraft wiring must withstand extreme environmental conditions. The correct insulation resistance test voltage ensures safe operation under high-altitude and variable-temperature conditions.

Automotive & Rail

Modern vehicles and rail networks use complex electrical systems. Proper test voltage levels ensure wiring harnesses and electronic components meet strict safety standards.

Energy & Renewables

Power systems, including transformers, generators, and wind turbines, require insulation resistance testing with high-voltage applications to prevent unexpected failures.

Manufacturing & Industrial Equipment

Factories rely on automated machinery with extensive electrical systems. Selecting the right test voltage helps prevent downtime and costly repairs.

Automating Insulation Resistance Test Voltage Selection

Automation has transformed the way insulation resistance tests are conducted, ensuring the correct test voltage is applied without manual intervention.

Key Benefits of Automated Test Voltage Selection

- Eliminates Human Error: Ensures consistent and precise voltage application.

- Faster Testing Cycles: Reduces time spent on manual setup and adjustments.

- Customisable Voltage Settings: Allows different voltage levels to be applied based on the equipment’s operational requirements.

- Real-Time Data & Reporting: Provides insights into insulation condition and predicts maintenance needs.

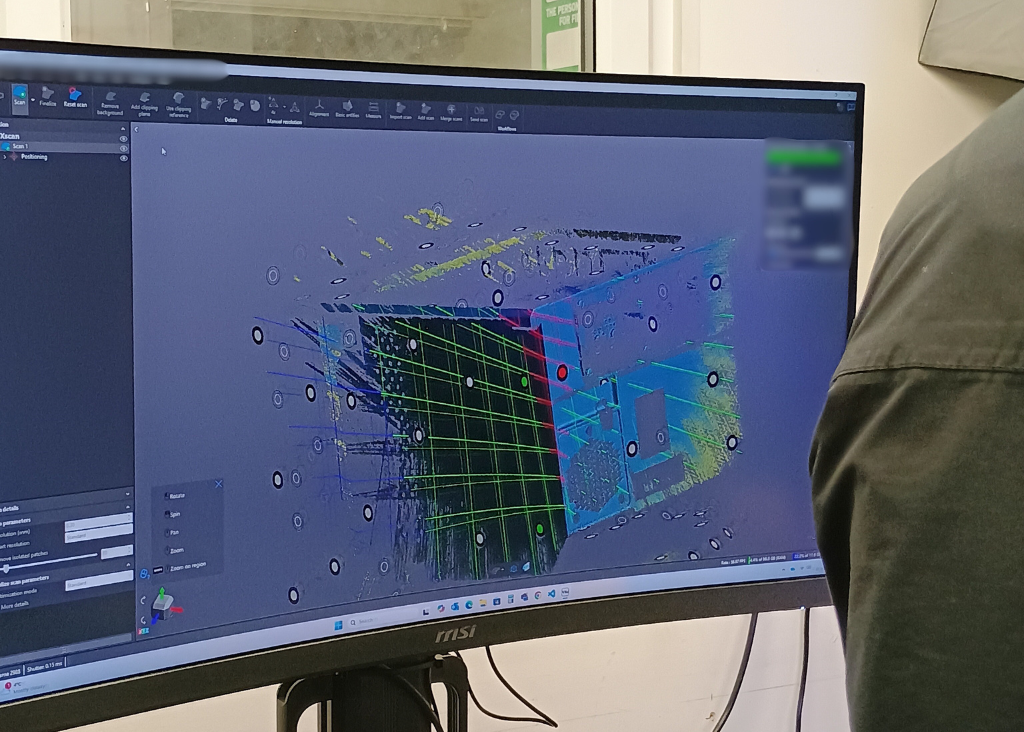

MK Test’s automated systems are designed to handle low, medium, and high-voltage insulation resistance testing, ensuring compliance with international standards while streamlining the testing process.

How MK Test Optimises Insulation Resistance Testing

At MK Test, we provide advanced automated insulation resistance testing solutions that:

- Apply the correct test voltage automatically based on equipment specifications.

- Offer customisable settings for industry-specific applications.

- Provide high-volume testing capabilities for manufacturing and maintenance operations.

- Integrate seamlessly into existing workflows, improving efficiency and compliance.

To explore how our solutions can enhance your insulation resistance testing process, visit our product page.

Choosing the correct insulation resistance test voltage is critical for accurate and safe electrical testing. Whether working with low, medium, or high-voltage systems, selecting the appropriate voltage ensures fault detection, regulatory compliance, and insulation longevity.

By adopting automated test systems, industries can eliminate manual errors, improve testing efficiency, and ensure the right voltage is applied every time.

For expert guidance on automated insulation resistance testing, contact MK Test at +44 (0)1823 661100 or email sales@mktest.com.

FAQs About Insulation Resistance Test Voltage

Q1: What happens if the test voltage is too high?

A1: Applying a voltage that is too high can cause insulation breakdown or permanent damage, reducing equipment lifespan.

Q2: How do I know which insulation resistance test voltage to use?

A2: The appropriate test voltage is determined by industry standards (IEC, IEEE, BS), equipment specifications, and manufacturer recommendations.

Q3: Can automated systems adjust test voltage for different applications?

A3: Yes, automated systems like those from MK Test can dynamically select and apply the correct test voltage based on the equipment being tested.