Introduction to fault analysis

At MK Test Systems, we’ve spent decades supporting industries such as aerospace, rail, and automotive in improving electrical wire harness testing.

This article accompanies our technical talk delivered at the Electrical Wire Processing Technology Expo (EWPTE) in Milwaukee, May 2025. In the session we shared practical insights into fault analysis and investigation, drawing on years of hands-on experience across our key sectors.

We explore how today’s test systems – particularly automated ones – are often underused. While they’re capable of capturing huge amounts of useful information, most are still only being used to confirm whether a test passed. We’re challenging that status quo and presenting ways to generate, store, and analyse more useful data to improve efficiency, reliability, and future readiness.

Fault Analysis: What you can (and should) be doing today

Move Beyond Pass/Fail

Many test teams only save passed results for traceability – a habit rooted in older systems with limited memory or paper-based reporting. Today’s ATE can store full datasets, including passes, failures, aborted runs, and partial results. Logging all of this gives you a fuller picture of test behaviour and trends, not just the final outcome.

Use Computer-Readable Formats

Test results can be exported in structured formats like JSON or XML. These formats are easy to search, automate, and analyse – even across thousands of tests. Unlike PDFs or printed reports, these data files can be reprocessed later to generate human-readable summaries, trace faults, or identify changes over time.

Record Metadata

Alongside test results, you can also log information like equipment serial numbers, cable IDs, temperatures, humidity, and operator IDs. This metadata is often overlooked but can provide important clues when investigating performance drift or inconsistencies.

Automate Program Generation

Manual creation of test programs is slow and error-prone – especially in high-mix, low-volume environments. Using APG tools that generate programs directly from CAD or schematics improves consistency, flags missing pins or mismatches before testing starts, and reduces reliance on highly experienced staff for setup.

Export Everything Automatically

It’s tempting to only store results when a test completes successfully. But valuable insights can come from tests that were aborted or restarted. Automatically exporting results every time – even for interrupted tests – creates a reliable audit trail and allows you to spot recurring issues like frequent setup errors or bad connectors.

Avoid Hidden Failures

Many test systems only report average values for resistance or insulation. But short-lived spikes or outliers – often caused by AC noise, mechanical stress, or intermittent faults – get lost in those averages. Today’s equipment can store full datasets, including min, max, and waveform data, allowing you to spot the subtle issues that could lead to future failures.

Fault Analysis: What You Could Be Doing Today

Join Up the Data

Wire harnesses are often tested several times throughout their lifecycle – at the supplier, during installation, and in final assembly. By comparing results across these phases, you can identify where faults are introduced or where performance is degrading. For example, if resistance values worsen gradually, it could point to connector wear or assembly stress.

Create a Common Data Platform

Different types of testers (bond, wire, hi-pot, RTS) often operate in silos. At MK Test, we’re working on unifying the data from all our test systems into one shared database. This centralised platform makes it easier to perform meaningful analysis, track trends over time, and correlate data from different stages or departments.

Label Failures Intelligently

When operators can enter free-text reasons for failures, it makes reporting messy and hard to analyse. Instead, limit failure categories to a defined list – such as “installation issue”, “tooling fault”, or “design mismatch”. Standardised labels make it easier to track patterns and train future AI tools to assist with diagnostics.

Automate the Kitting Process

A surprising number of test failures come down to simple errors like missing or misconnected cables. These are often caused by unclear kitting lists or reliance on tribal knowledge. Your test program already knows which adaptors are needed – so use that data to create automatic kitting checklists, or interface with smart storage to ensure nothing is missed or left behind.

Fault Analysis: What You Should Be Thinking About For The Future

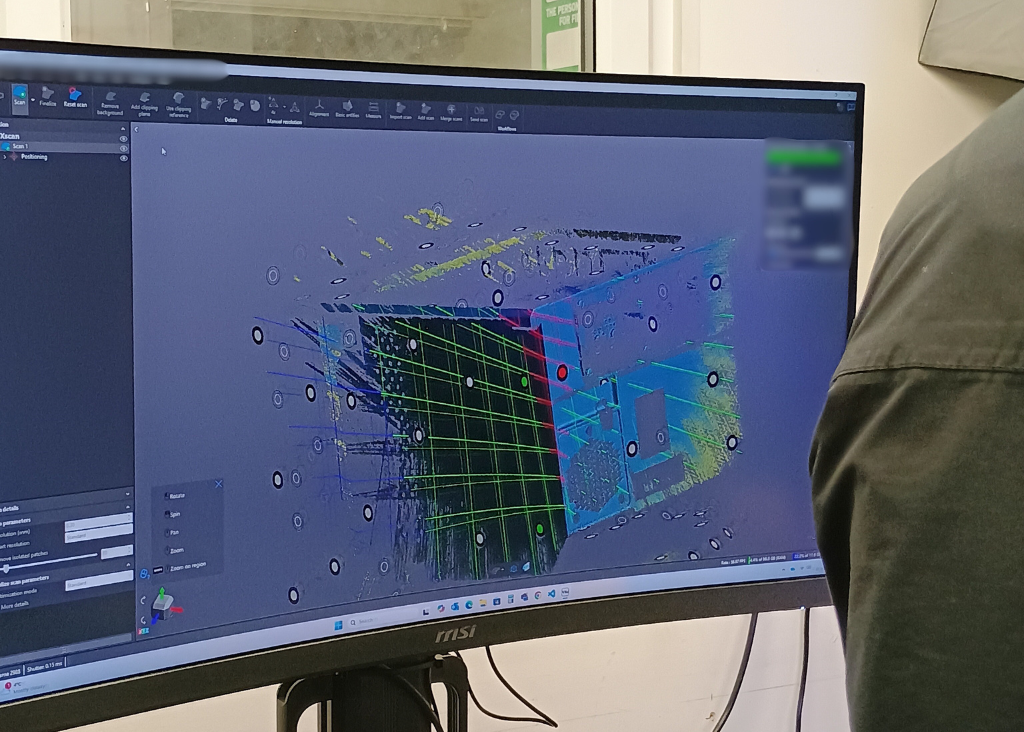

Real-Time Scanning

Real-Time Scanning (RTS) allows continuous testing throughout the build process, not just at the end. It runs at a safe low voltage, so operators can leave it running as parts are installed or connected. This helps catch faults like loose crimps or damaged cables in the moment they happen, rather than after the fact.

Test Optimisation with AI

If your test system sees that power supply tests fail most often, why run them halfway through the sequence? By reordering the test steps based on historical data, you can surface the common failures earlier – saving time and reducing frustration. Better still, this reordering can be handled automatically by the system.

Augmented Intelligence

While full AI decision-making isn’t acceptable in many safety-critical environments, “augmented” intelligence can support human operators. Think of it as giving your team a virtual assistant – surfacing relevant data, spotting patterns, and flagging potential issues, while leaving final judgement with the engineer.

Automatic Fault Location

In large vehicles or platforms, finding a wiring fault can take hours. Distance-to-fault technologies can pinpoint the location of a break or short circuit to within a few centimetres. This means engineers can go straight to the problem area, reducing downtime and risk of further disruption.

Augmented Reality

By overlaying test data onto real-world views using tablets or AR glasses, operators can see visual cues like resistance changes, intermittent faults, or connector IDs. Add in interactive instructions or animated guides and you give new technicians a huge boost in confidence and accuracy – with less training time required.

Conclusion and next steps

Much of today’s test technology is underutilised – not due to limitations in the equipment, but due to legacy processes and outdated habits. By rethinking how you generate, label, and use test data, you can improve reliability, reduce time to resolution, and start preparing for smarter, more connected test environments.

At MK Test Systems, we’re already helping customers take these steps. If you’d like to discuss how we could support your test strategy, we’d be happy to help. For tailored advice or to explore how MK Test Systems can help improve your test processes, please get in touch.

Downloads:

- Download the Fault Analysis tech talk slide pack here from EWPTE 2025 here

- And the accompanying LightPaper here