Sustainability

At MK Test Systems, sustainability is at the heart of how we think about the future of our business and our role in the world.

As part of the Halma group, external sustainability reporting requirements are increasing over the next five years.

This page aims to provide a snapshot of what we’ve already done, what we’re currently working on, and what we aim to achieve next.

Our sustainability vision

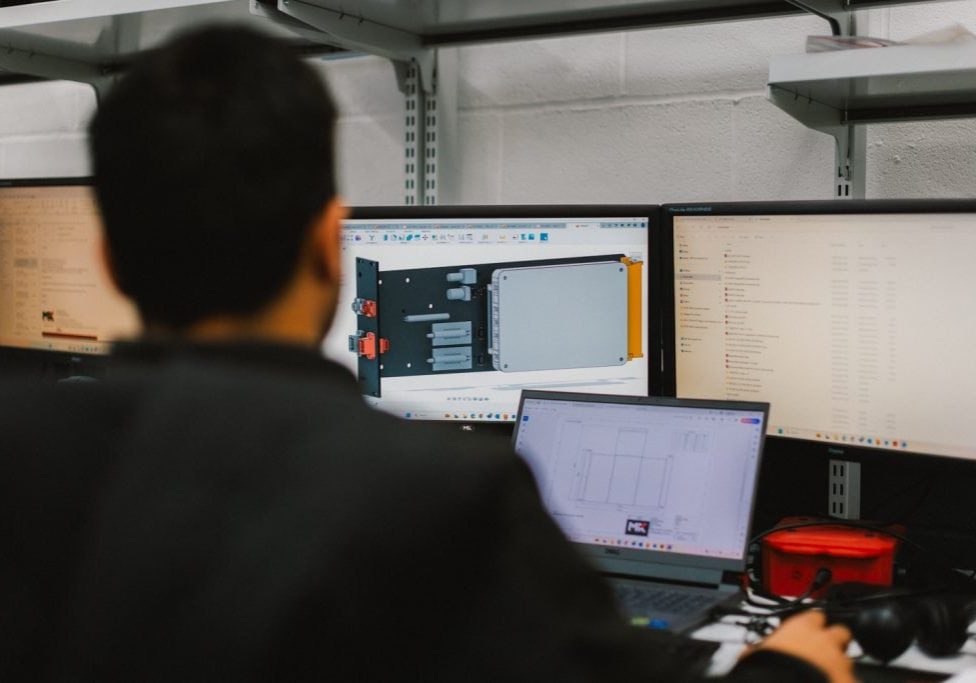

“Our sustainability vision is clear: we aim to provide high-quality automatic test equipment that supports the electrification of future technology. By doing so, we contribute to creating a safer, cleaner, and healthier future for everyone.”

Paul Fishwick, MK Test Systems Operations Director

Smarter, Greener Shipping for the ExLRT

We’ve switched from shipping our ExLRT product in wooden crates to a new, custom Tuffwall box. This durable, quadruple-walled box is designed to fit the ExLRT Peli Case perfectly, with no need for extra packaging.

The new packaging reduces both our carbon footprint and costs. We’ve seen savings of around 80% on UK shipments and over 55% on US deliveries. Plus, the lighter weight means we can now access an extensive express delivery network, giving us more flexibility on pricing and delivery times.

We’ve tested the new box in real-world conditions, and it held up brilliantly – no damage to the product, and the box remained intact. The first ExLRT system was shipped using this method in May 2024, and it’s been such a success that we’ve also rolled it out with smaller cartons for ExLRT spare parts and calibration standards.

In progress

We’ll soon be installing electric vehicle (EV) charging points at our premises. This will make it easier for employees and visitors to switch to EVs and is a practical way to support low-emission travel options.

Alongside this, we’re upgrading our facilities with intelligent LED lighting. These lights adjust to occupancy and natural light levels, which helps reduce energy use without compromising comfort or visibility.

We’re also looking at ways to reduce the volume of support-related travel within the EU. This could involve making better use of remote support tools, increasing local knowledge-sharing, or adapting service routes – all with the aim of cutting down on unnecessary emissions.

In parallel, we’re developing a framework for tracking our sustainability progress using key ESG (Environmental, Social, and Governance) performance indicators. These KPIs will help us monitor our impact, set clear targets, and report back more effectively to stakeholders including Halma.

Future sustainability goals

Looking ahead, we plan to develop greener versions of our test systems. This includes identifying more energy-efficient components and materials with a lower environmental footprint, while maintaining the high performance our customers expect.

We also intend to carry out a full review of the cables and connectors used in our equipment to assess their environmental impact. By exploring alternatives with better sustainability credentials, we can improve the overall footprint of our products.

On the supply chain front, we’ll be piloting the use of sustainability questionnaires with key suppliers. This will help us better understand the practices of those we work with and encourage more environmentally responsible sourcing and partnerships.

We’re continuing to identify Sustainability Champions within the business. These individuals will represent their areas, help drive local initiatives, and serve as a link between teams and wider company sustainability efforts.

Finally, we’re committed to meeting Halma’s evolving sustainability reporting expectations. We’ll be building on the foundations we’ve laid so far to create a more structured and transparent approach to reporting our progress.