High Voltage Insulation Cable Testing

Setting the industry standard for HV testing.

High voltage insulation testing helps identify weaknesses or degradation in cable insulation that could lead to faults or breakdowns, thus preventing electrical hazards or failures in power transmission systems.

The Automeg® tester is commonly used for testing the insulation resistance of high voltage cables. This type of high voltage insulation testing is essential for ensuring the integrity and safety of HV electrical systems.

Automeg

Faster inspection times, greater accuracy.

Automeg® streamlines QA for manufacturers by automating the high voltage insulation cable testing testing process to quickly identify issues and enhance efficiency and reliability.

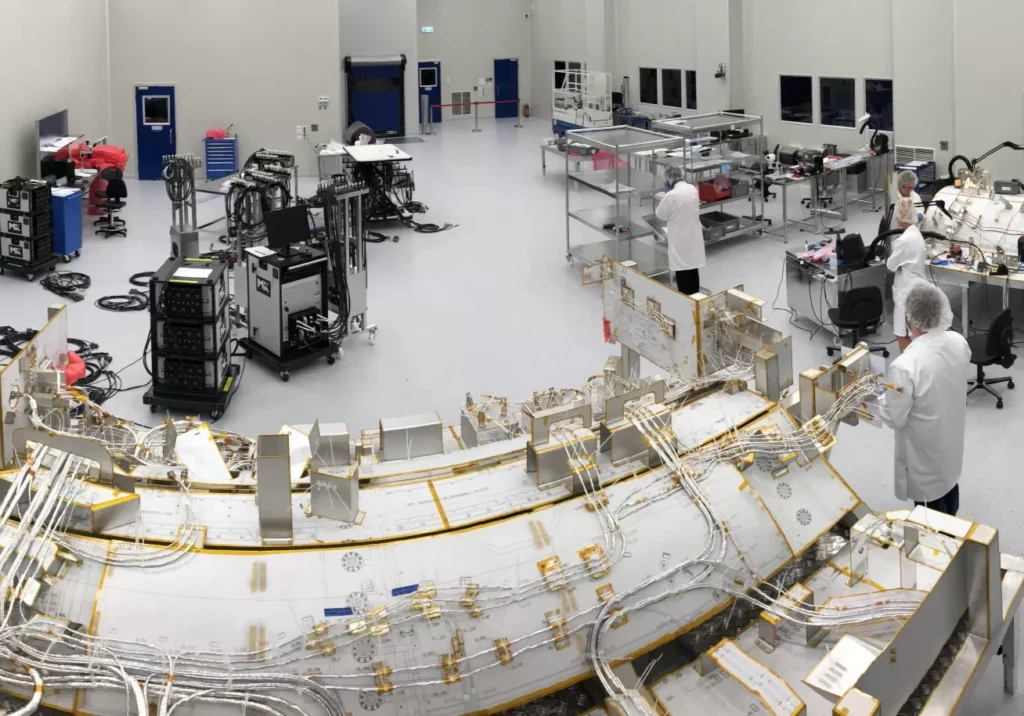

Perfect for manufacturing and maintenance environments, the Automeg reduces turnaround times while maintaining the highest performance standards, making it essential for quality assurance in automotive, aerospace, rail, and beyond.

Why choose Automeg for your high voltage insulation testing:

Automeg testers are designed to test a variety of cable types under high-voltage conditions (1kV to 10kV) while accurately measuring insulation resistance (in MΩ or GΩ) to ensure performance and reliability.

Automeg systems can include built-in safety features to prevent accidental exposure to high voltage. These may be:

Over-voltage protection

Leakage current monitoring

Interlock systems

Automeg supports various cable types, including power, communication, fiber optic, and control cables, with features like automatic test procedures, digital display, and data logging for efficient and user-friendly operation.

Contact us to request a quote, demo or more details about our HV insulation test solution.

Case Study

Subsea HV Cable Testing

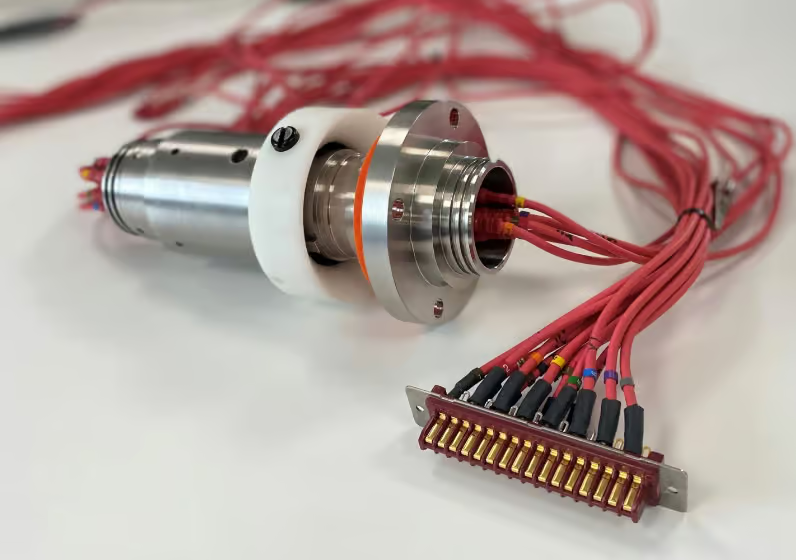

One of our customers for subsea oil and gas applications uses the Automeg for testing high voltage insulation cables and connectors to determine and verify the safety of their electrical insulation.

The high voltage insulation testing is being used to verify:

- Insulation resistance

- Breakdown voltage

- Leakage current

The customer is performing tests at 3500V DC underwater to check for arc and insulation failure between the shield and the back shell of the connectors.

Our Automeg system has a safety integration that prevents the person from having direct contact with the harness assembly.

Resources

Want to see more use cases?

Browse the rest of our application examples, searchable by lifecycle stage or industry, to find your best fit.