MK Test recently undertook a project where no 3D engineering data was available, as the products requiring test were developed many years ago. Traditionally, this scenario would require reverse engineering using conventional measurement techniques, adding time and complexity to the development process.

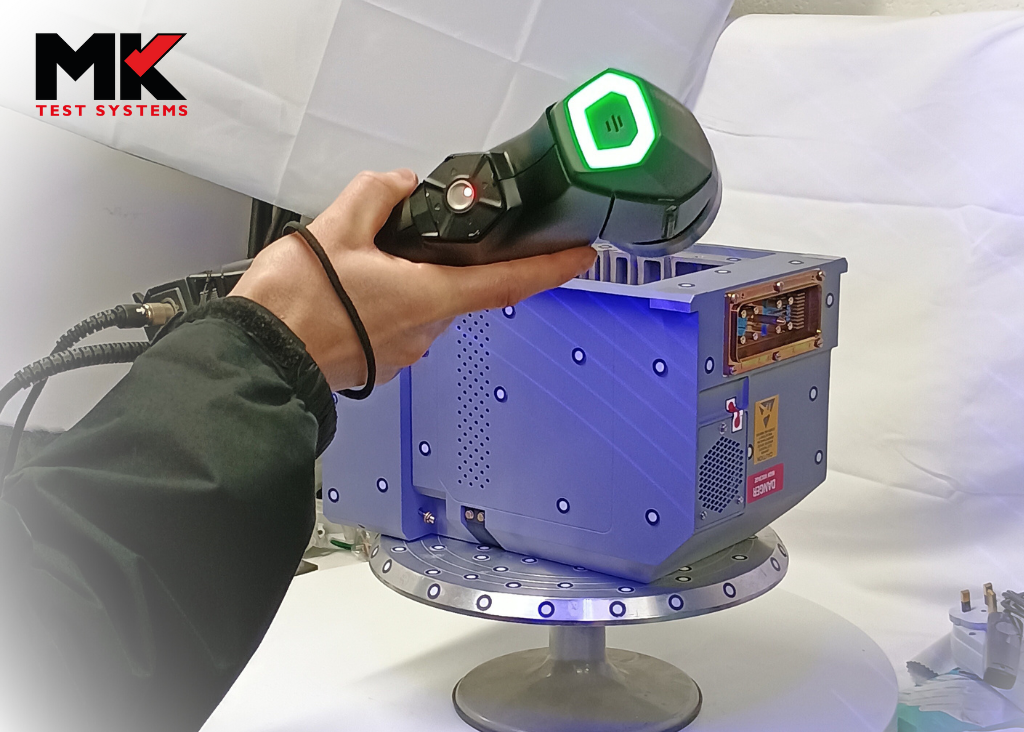

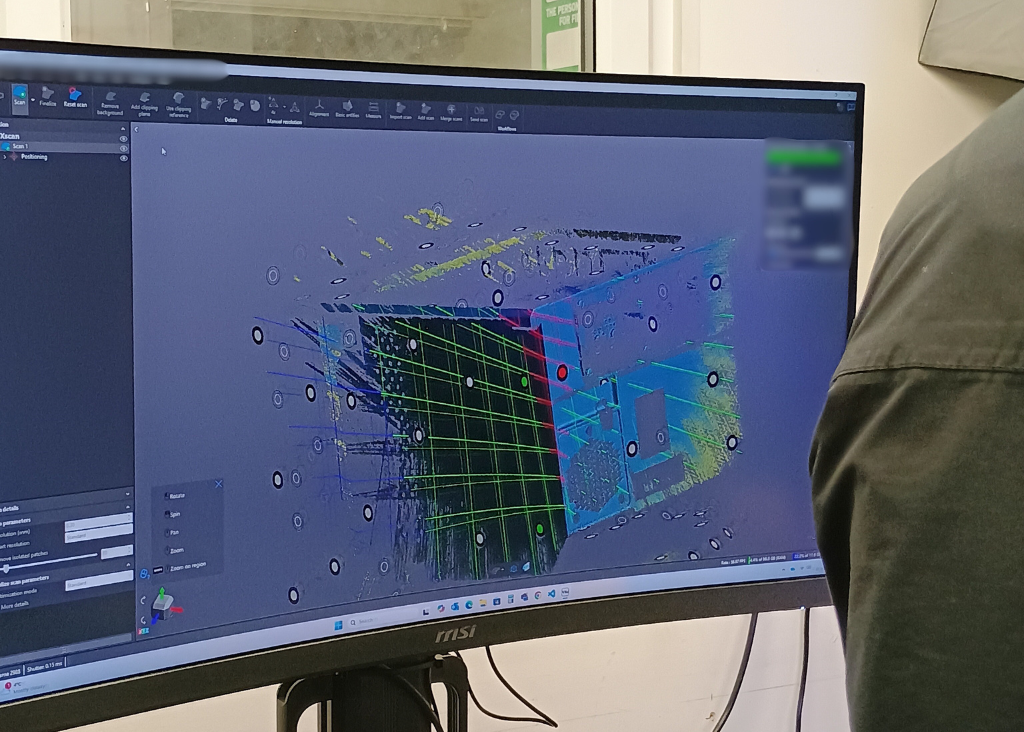

For this project, the customer supplied one of the existing modules, allowing us to work with a specialist engineering partner to carry out high-resolution 3D scanning. A metrology-grade, seven-beam laser scanner was used to digitally capture the shape and surface detail of the module, collecting millions of XYZ data points to accurately define its geometry within our 3D design software.

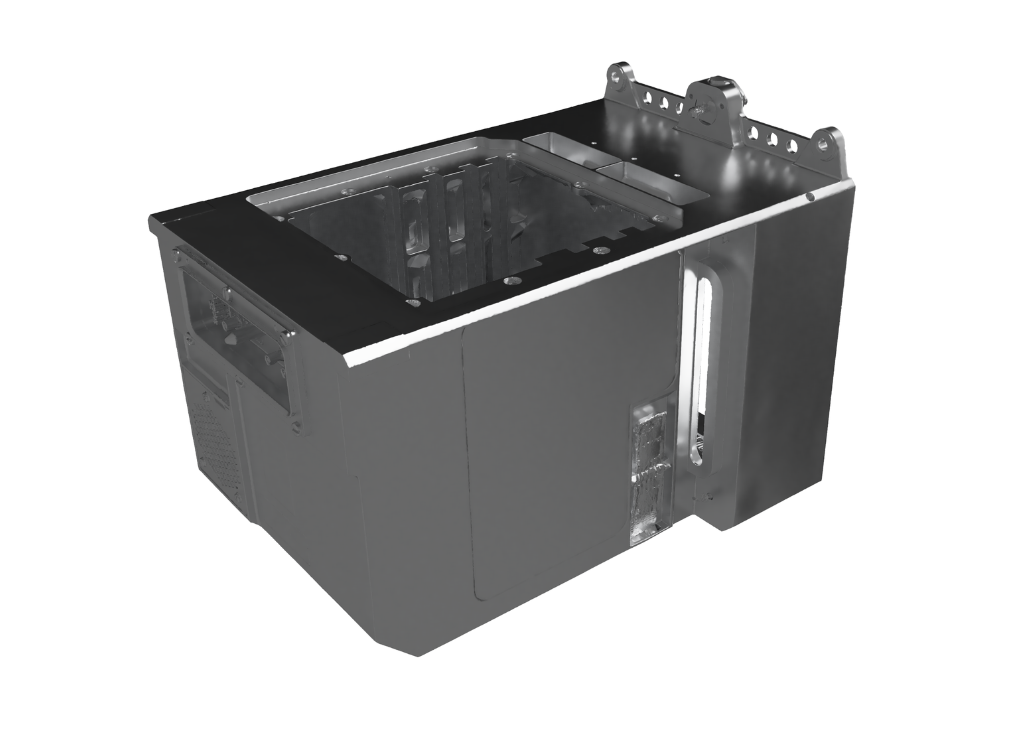

With this detailed digital model in place, we can design, validate and finalise the required tooling and interface modules with confidence. The result will be a robust solution that integrates smoothly with the customer’s existing MK Test equipment, while reducing development time and avoiding the limitations of traditional reverse-engineering methods.

This project highlights how innovations such as 3D scanning play a key role in how we support our customers. By combining advanced technologies with practical engineering expertise, we can overcome legacy challenges and deliver smarter, more efficient test solutions that extend the life and capability of existing systems.

Learn more about our innovation focus as part of our business values here. Our Tech::Lab page also provides information about our latest R&D and NPD projects.

This article was written by Mark Sanders, Senior Production Engineer at MK Test Systems.