This post looks at wire harness testing, and the significant productivity and quality benefits of using automatic testing equipment. It includes an introduction to digital techniques, which use test data for developing more efficient testing methods.

An introduction to wire harnesses

Copper wires can carry electrical power or data signals – wire harnesses can contain either one or both of these wire types. Wire harnesses are installed into a huge range of products, vehicles and equipment within the aerospace, defence and rail sectors as well as consumer goods, automotive and many more.

Regardless of a harness’s constituent wires, cables, or target application, testing is always an essential part of the manufacturing process. Ensuring that the harness has been correctly assembled avoids the risk of a field failure with its associated cost, delay, and reputational harm. It also proves compliance with any relevant product quality standards.

For a simple wire harness comprising a couple of cores, for mains power or low frequency data signals, manual testing may be a feasible and cost-effective solution.

The challenges of wire harness testing

However, if the harness has a larger number of wires, cables, is of significant length, and/or has to carry high-frequency data signals, testing rapidly becomes a more challenging issue. In this instance, the number of terminations that could be mis-connected or shorted rises sharply, and more parameters will need to be tested. Additionally, the harness may contain contactors, Zener diodes, LEDs or other components as well as the wires and cables.

If working on complex harnesses, technicians performing manual testing will find it impossible to keep pace with production output, while also maintaining consistent accuracy in their test procedures as well as locating and rectifying any faults revealed by testing.

The solution, then, is to use automatic electrical test systems that can provide the necessary testing faster and with great accuracy. But what exactly do such systems entail, and how are they evolving in line with modern manufacturing requirements?

Let’s look at the range of tests typically performed on cable and wire harnesses, and how they can be facilitated by modern automatic test equipment.

Automatic wire harness test system functionality

Continuity testing and resistance measurement are basic functions that check for incorrect or mis-wiring, loose connections, incorrect wire gauge, failed or incorrect components, bad joints, and crimps. Short circuit testing will also find crossed wires and any unwanted connection or conductor path. Test equipment can also provide Distance to Fault indication to reduce time taken for locating open and short circuit failures.

Two-wire resistance testing can be used if accuracy down to 0.1 ohm is sufficient. If greater accuracy is required, four-wire Kelvin testing can be employed. By eliminating fixture resistance from the measurement, this can yield accuracies to 0.001 ohm.

High voltage DC insulation resistance testing can find damaged or faulty insulation by measuring the specific insulation resistance value of each conductor or group of conductors. Similarly, high voltage DC and AC Hi-pot and dielectric tests can reveal damaged or faulty insulation by measuring the specific current leakage value for each conductor or group of conductors, using high voltage DC or AC respectively.

For higher-frequency data transmission, cable capacitance can become a problem. The output impedance of the driver in combination with natural cable capacitance create a parasitic low-pass filter. With high enough cable capacitance, this will drastically distort the measurement pulse and introduce an error. Accordingly, testing can include checking for correct capacitance in shielded cable, coaxial cable, twisted pairs, and components/capacitors.

Modern testing equipment should be able to accommodate cable or wire harnesses that include circuit components like diodes, resistors, Zener diodes, transformers, inductors, fuses, transistors, sensors, and others, or electrical devices such as relays, contactors, motors, actuators, and solenoids. Functional testing can be performed by stimulating the active component and measuring or detecting its response. Automatic test equipment with software controlled power supplies can automate and accelerate this stimulation and measurement procedure.

What are the most valuable features of test management software?

While the test functions listed above are essential to the wire harness tester’s utility, they are not the only factor.

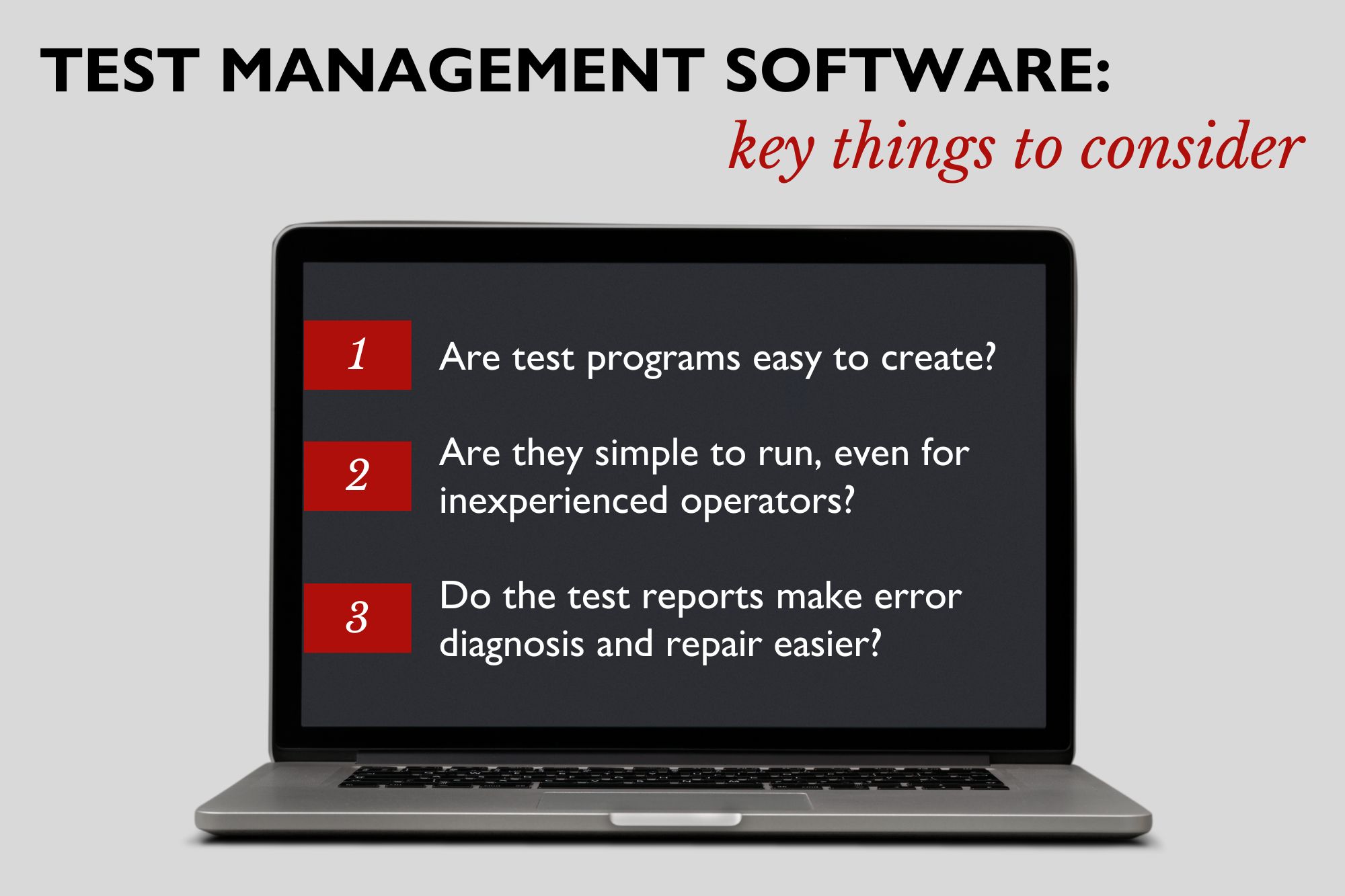

Ultimately, the equipment’s value to its user relates to how easily, and how well, it delivers actionable data. This in turn depends on its associated test management software, which has three critical considerations as shown in the infographic opposite.

Some testers have an Auto Learning facility, where the system automatically interrogates the connections within a harness. It then creates a test programme accordingly. If the programme is then validated as good, it becomes a reference or ‘golden’ harness test programme for ongoing use.

Test programmes can also be created manually, by importing data from external databases and text files.

Import and translation from other test systems is also possible. However, most users employ automatic programme generation, or APG. APG can be initiated by using a connections table showing how connectors and pins are interconnected, and an X-ref file showing how the tester is connected to the product.

Generated programmes can contain user-configurable test instructions and input options to guide operators through the test process. Operator displays should deploy graphics effectively to make the graphical user interface (GUI) as intuitive and user-friendly as possible.

Test results can then be held in a database for future review. Reports, configured for specific applications, can be generated in hard copy or electronic format.

Real time validation and digitisation

While automatic wire harness test equipment significantly improves quality and productivity, manufacturers are continuously seeking opportunities to reduce the amount of testing needed.

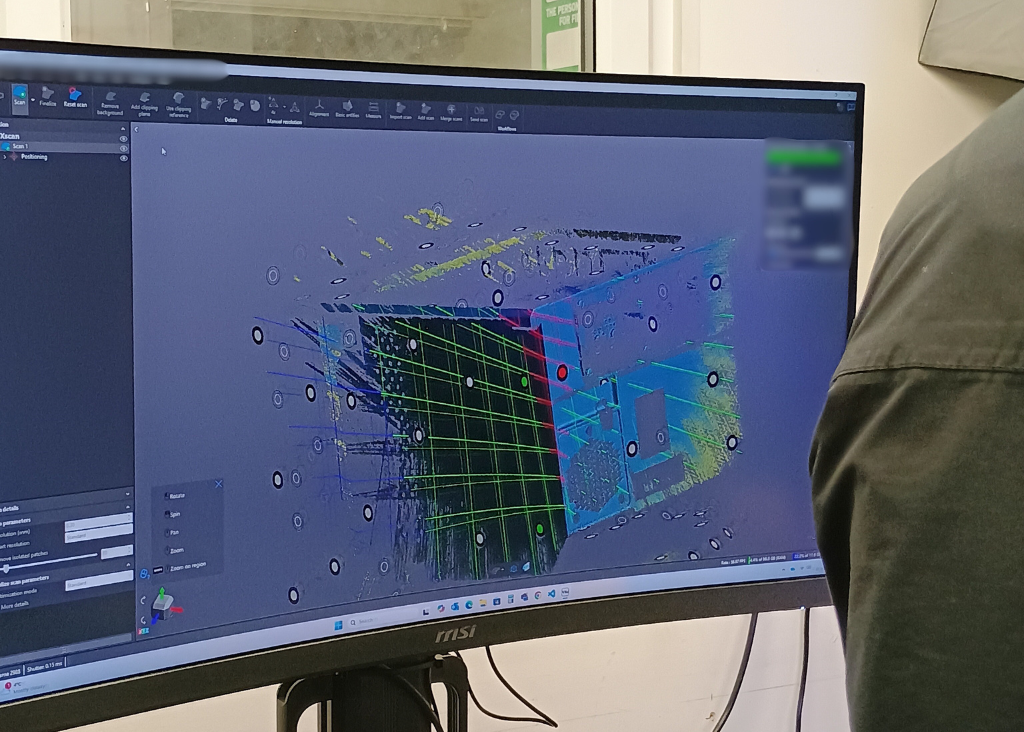

The latest testing technology is creating these opportunities through the use of ultra high speed measurement algorithms, solid state switching, and real-time validation of harnesses and connections as they are constructed; this allows OEMs to redefine the production process and achieve huge time savings.

These benefits can be realised by digitisation of the data yielded when running a test programme. This can then be analysed to understand specific, regular types of failure and an opportunity to design out the causes. The effect of moving specific tests to other production stages can be assessed. The result? A harness which is fully tested in the shop may not need tests repeated at installation stage.

Additionally, analysis of data and associated statistics can quickly identify common faults and changing trends. This can highlight material batch issues, changes in supply chain quality, and specific training needs. It is also possible to identify tests that never fail, enabling decisions on whether they are stringent enough or, conversely, not required.

More information

To learn more about our cable and wire harness testing solutions, visit our Automeg and RTS product pages. More information on MKAT, our test management software is here. To discuss how we can provide a test solution specific to your production environment, please contact us for a no-obligation chat.

We run regular training FREE webinars showing how to use our test systems. Everyone is welcome to these training sessions – you don’t have to be a customer to attend. Find out more and book your place here.